39mm Round Axle suit Standard Bearings and made in Australia

39mm Round Axle suits small box and boat trailers. 750kg is the maximum rating for LM or standard bearings. Measure axles from the tip of the thread to the end of the thread. Quality axles are not easy to manufacture. Let's run through the process from the video below.

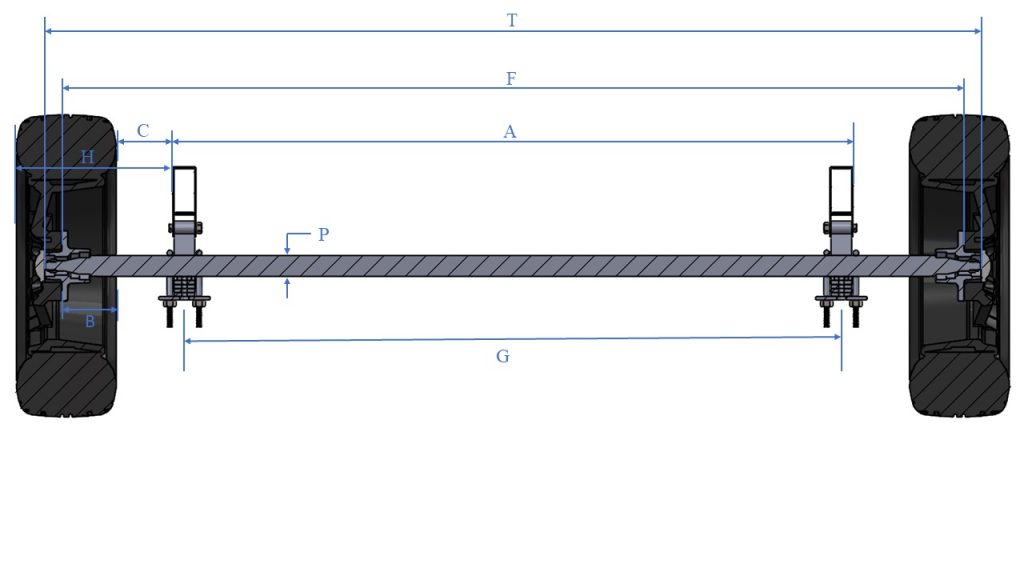

How to measure bare or straight axles

Measure bare or straight axles from tip to tip.

- A solid beam of steel is cut to the correct length.

- Couplemate developed a program to use a roughing tool, a finished tool, and a threading tool.

- The first tool used in the video is a roughing tool. This tool removes most of the steel before we arrive at the finishing profile.

- The finishing tool skims over the profile and produces a journal within 0.02mm.

- Once the finishing tool has done its job, a threading tool is engaged, cutting a thread within 0.02mm of its specification.

- The CNC technician manually fits the front and back bearings to ensure a tight fit. The axle nut is then tested for tightness.

- Finally, the axle is removed from the lathe if all the above steps pass.

Standard or LM Bearing Sizes are

- Inner ID 31.75mm, OD 59.10mm

- Outer ID 19.05mm, OD 45.20mm

- Seal ID 37.5mm, OD 59.10mm

- Dust Cap 45.20mm

Couplemate manufactures 39mm round trailer axles in Wynnum, Queensland. BlueScope or One Steel provides the best axle money can buy. If you can find a better product, please tell me. The 39mm Round Axle is perfect for your trailer, caravan, or camper if you tow your rig straight and true. If not, then below are a few tips.

Common problem:

- Too much weight will bend this 39mm Round Axle to experience excess axle flex. You can read about axle flex and vibration here.

- Axle flex occurs when heavily loaded trailer springs rebound on the highway, causing the axle to flex up and down in the middle of the axle.

- Springs to fatigue - fail prematurely under axle flex loading conditions.

- If the load is over 750kg, axle flex will occur.

- If the axle is 39mm round and bending, buy a 45mm round axle and update it to 1.5t.

- It is not expensive in comparison to replacing springs that have suffered fatigue.

Other Common Problems:

- Rough seal journals can cause a loss of grease through the rear seal.

- Some suppliers supply non-virgin or scrap steel and forge this steel into a solid square or round shape for axle production.

- Chinese bearings are the second most significant cause of axle failure. If you plan to drive on the highway, use Japanese bearings. The combination of Japanese Bearings and 39mm round Axle will help you significantly with lower maintenance for your rig.

Calculating The Correct Axle Measurements

As a result of viewing the video above, calculate the face-to-face measurement.

- Measure the offset wheel. The wheel offset is the distance between the hub's inside and the rubber's outside.

- Add 50 mm to the offset. Alternatively, choose the distance between the rubber and the chassis.

- Multiply by 2 for both sides. Add your chassis width to the above number.

Still unsure of what measurements to take? Check out this handy guide below:

[P] - Check material specifications. What size and profile is the axle (for example, 45mm Square)

[T] - Overall axle length (tip to tip)

[F] - Hub face-to-hub face measurement

[A] - Chassis width

[C] - Tyre clearance

[B] - Back offset

[H] - Tyre to chassis

[G] - Axle pad centres

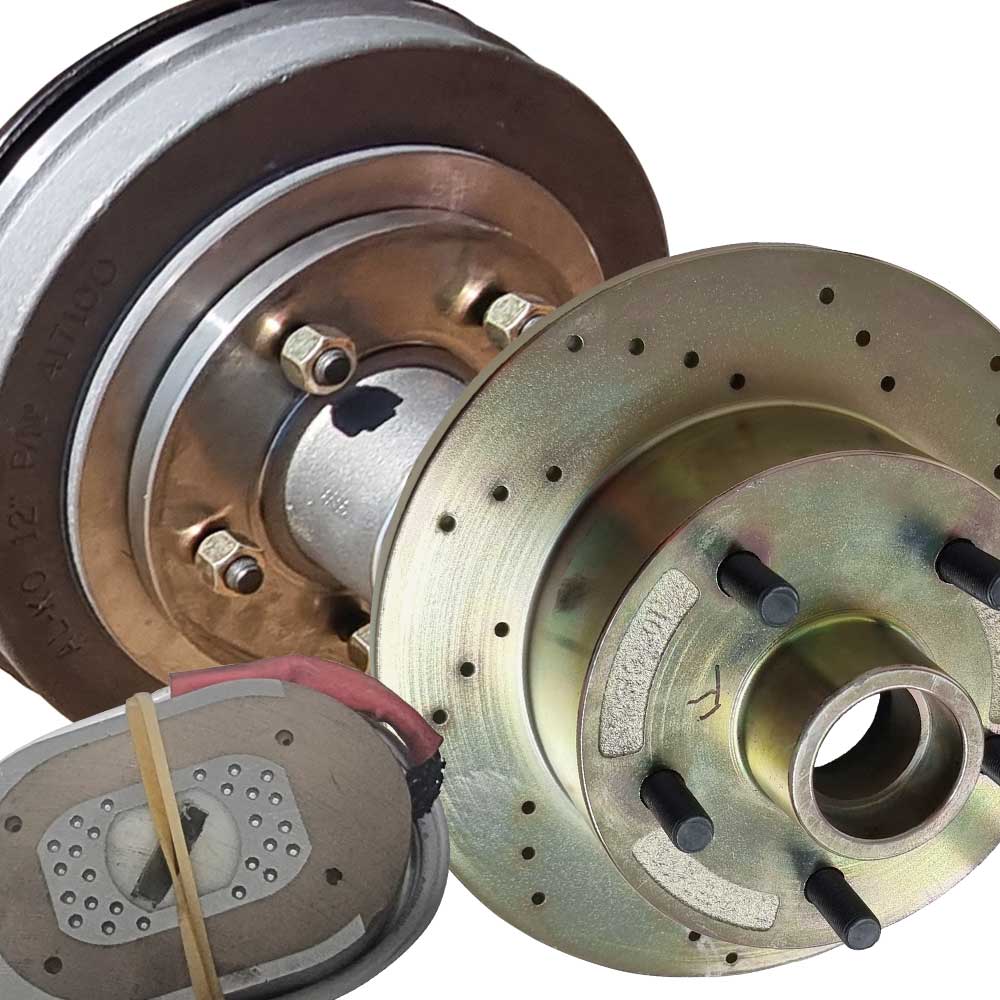

Identifying Bearing Combinations

You will also need to identify your bearing combination, which can be done by pulling off a hub and bearings and locating the number laser engraved onto the bearing. You will require both the inner and the outer bearing number.

Additional information

| Weight | 19 kg |

|---|---|

| Dimensions | 200 × 4 × 4 cm |