24v Electric Brake Magnet

24v electric brake magnet for 24vdc braking systems has arrived. Recommended replacement of 12v magnets in cases where low voltages exist.

The innovation of the 24vdc electric brake magnet overcomes problems with 12vdc tandem electric braking systems worldwide.

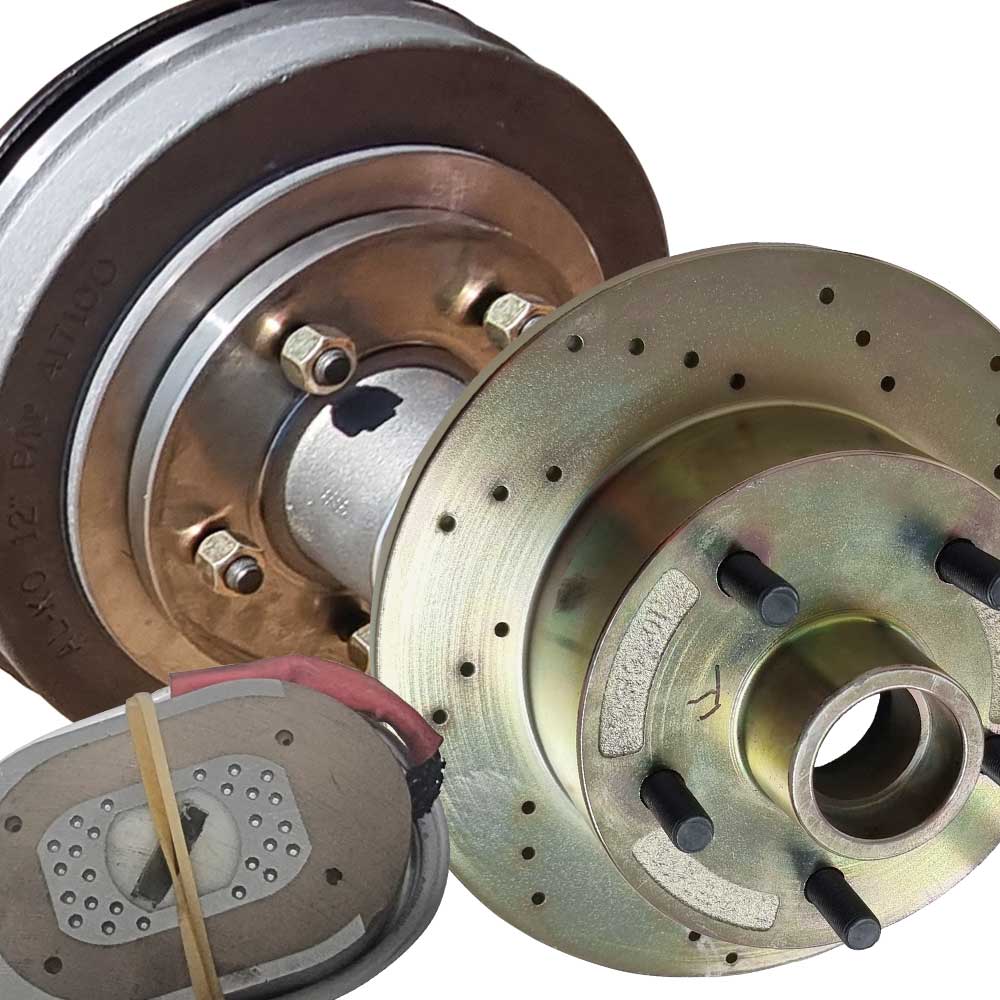

Suitable for 10-inch and 12-inch tandem braking systems.

If you have a 24v plug in the back of your truck of bus, you can use these magnets in our standard backing plate systems to avoid using a reducer.

Precautions

- Test the braking power wire on the car side of your trailer plug. It should be 12v or more.

- If 12v or less, run the car, so the alternator feeds the electrical system and replicates actual driving conditions. This will boost the voltage supply.

- Test the voltage at the 1st and last magnet in the trailer wiring loom.

- This test must be completed not using the breakaway kit because you must include voltage losses from the car battery and not the breakaway kit.

- Sometimes, we have tested less than 4 volts at the last magnet. We would, therefore, recommend replacing the magnets with Couplemate 24v magnets and installing a 12v to 24v converter.

What is the practical purpose of 24vdc?

The majority of Trucks have 24vdc electrical systems. Trucks towing trailers use a 24vcd to 12vcd brake controller to activate the trailer brakes. The brake controller contactor is activated by a signal from the truck brake lamps.

The same voltage drop problem exists on the trailer; however, trucks have better braking systems, so in most cases, the operator can not feel his bad trailer brakes.

When trucks are overloaded, operators report trailers are not stopping.

How do I get full power from my Caravan or Trailer Electric Brakes?

The braking solution for towing a caravan or trailer is relatively simple.

- Change the 12v magnets to 24v magnets on the electric backing plates.

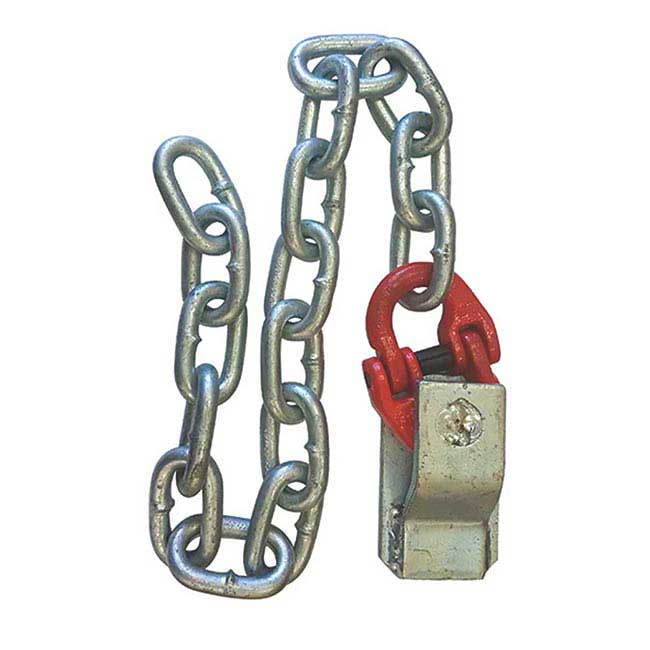

- Install a 12v to 24v converter after the breakaway kit.

- Connect the 24v converter to the new 24v brake magnets

Where do I install this converter?

To convert 12vdc to power 24v magnets, install this converter after the breakaway switch and before the first electric brake.

How to check magnet wear

- Check the four small holes on top of the magnet.

- These holes are warning indicators that display magnet wear.

- If there are no holes or fewer than 4 holes.

- When the face of the magnet hole has worn then, it is time to replace the magnet.

Key Features

- Wear holes are at 3 pm, 6 pm, 9 pm and 12.

- Magnets draw approximately 1.6 amps each @ 24v

- Wires can be connected either positively or negatively.

Once worn, copper begins to become exposed; subsequently, an open electric circuit will render the brakes inoperable.

TIP:

- New magnets need to be bedded into position before 100% of braking is achieved.

- The magnet face is a shiny finish.

- This finish needs to be scuffed up during the initial stages of breaking before your magnets become 100% effective.

- Caution, do not install new magnets on brake drums damaged by the old magnets.

Additional information

| Weight | 0.4 kg |

|---|---|

| Dimensions | 10 × 5 × 3 cm |